Axel

Active Member

Hi,

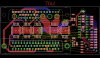

First of all I would like to introduce myself. I´m Axel, and I like my hobby - work at my 2 shovelheads (what is somehow similar to tractor engineering...) However, I developed some electronicboxes for custom bikes (look at www.elektronikbox.de) and I wondering if there is any 1:1 copy of the EHC available? I have read the discussions about the connectors and I know it is a challenge to get a good and reliable connection with the "printer style" connectors. I just got a EHC from a client. He would like to get a new EHC copy with a build in D-Box (http://www.elektronikbox.de/ebox_d_uk.xhtml). I found some similar industry connectors from Molex Does it makes sense to make some more copies of the EHC for other clients as well? What are the main problems of the old EHC module? Every suggestion would help. I don´t want to invent the wheel again...

Thanks a lot in advance for your answers and sorry for my lousy english...

All the best!

Axel

First of all I would like to introduce myself. I´m Axel, and I like my hobby - work at my 2 shovelheads (what is somehow similar to tractor engineering...) However, I developed some electronicboxes for custom bikes (look at www.elektronikbox.de) and I wondering if there is any 1:1 copy of the EHC available? I have read the discussions about the connectors and I know it is a challenge to get a good and reliable connection with the "printer style" connectors. I just got a EHC from a client. He would like to get a new EHC copy with a build in D-Box (http://www.elektronikbox.de/ebox_d_uk.xhtml). I found some similar industry connectors from Molex Does it makes sense to make some more copies of the EHC for other clients as well? What are the main problems of the old EHC module? Every suggestion would help. I don´t want to invent the wheel again...

Thanks a lot in advance for your answers and sorry for my lousy english...

All the best!

Axel

welcome from Pa.

welcome from Pa.