Mr. Wright

Knows some things

I want you all to hold up on your comments on this, until I finish my research. I ran into a perfect opportunity to test some theories on clutch adjustments, on the nine plate easy pull clutch.

We all know how hard it is to get it adjusted so that you can find neutral. I have not found it a problem in my shop to do this, until this last bike. I installed a complete new clutch, and with the rod adjusted all the way in, not backing the rod off any, and adjusting the cable until there was absolutely no slack in the lever, the bike still pulls forward when you put it in gear.

I told the customer to ride it for a few days, and get it loosened up, and bring it back so I can do these tests. When he brought it back, I found that it had loosened up enough that the bike would sit there in gear, but we still couldn't get it into neutral.

This is the tests I've done to rule out some of these theories I've read about and people have said they have done.

First off I got out my grandfather's trusty fish scale, tied it to a rope to see how many pounds it takes to pull the lever. The scale says 20 lb.

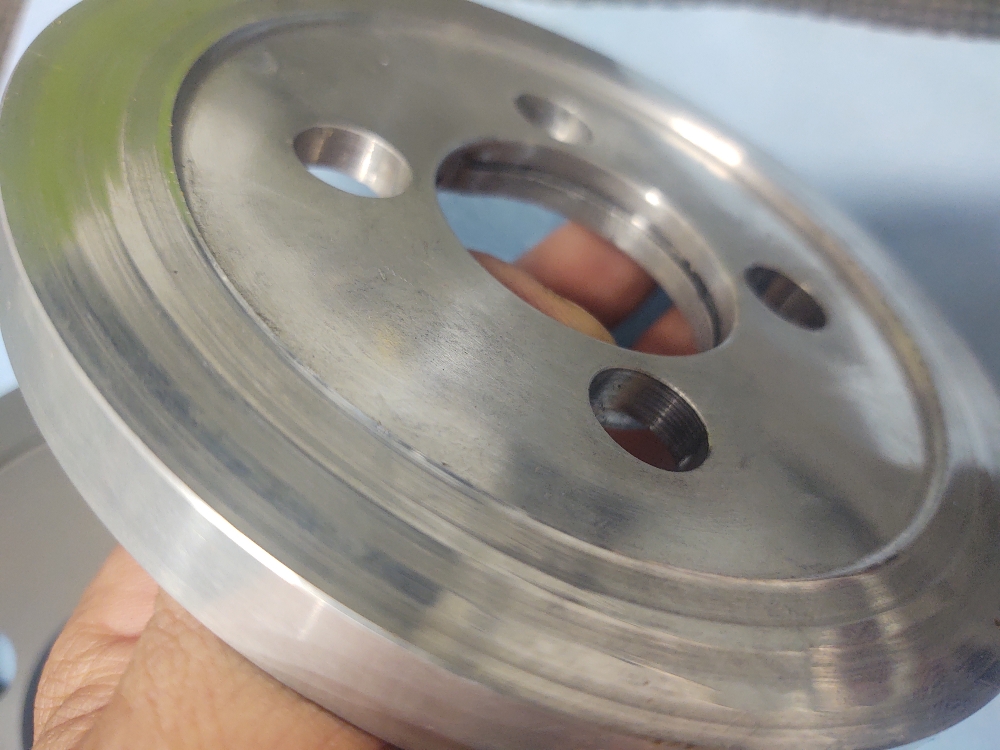

Next I took the ball ramps apart, clean them up, and attached three Earth magnets to the bottom plate. Then I set it on top of my vise, so that it when it was turned it would hit against the vice Jaws. Not that this is the actual distance that the cable would pull the ramp, but it is a distance that I can repeat for what I'm looking for.

Next, using the stock 3/8 diameter ball bearings, I measured how far the plates moved apart, and then repeated the same test using the 13/32 ball bearings, which are the next size larger. Both ball bearings spread the plates exactly the same distance.

Next, I took a set of regular ball ramps, and mismatched them to see what the lift would be. I did manage to gain .010 using the stock upper plate, with an easy pull bottom plate. Switching them the other way, it would not lift it at all. The problem is the slots on the two plates do not match up.

I did reassemble the bike, using the easy pull bottom plate and a regular top plate. Readjusted the clutch, and when I adjust the slack out of the cable you can see that there's only a quarter inch of threads where there is normally half inch better.

This did add 4 lb to the clutch handle pull, and did absolutely nothing on helping me find neutral.

Next we'll move to the handle to see if anything's loose up there. I am also in contact with HDM, on handle designs. This is because I have another bike sitting right next to it with a different style handle on it that has absolutely no problem getting into neutral.

More info to come as I do research

We all know how hard it is to get it adjusted so that you can find neutral. I have not found it a problem in my shop to do this, until this last bike. I installed a complete new clutch, and with the rod adjusted all the way in, not backing the rod off any, and adjusting the cable until there was absolutely no slack in the lever, the bike still pulls forward when you put it in gear.

I told the customer to ride it for a few days, and get it loosened up, and bring it back so I can do these tests. When he brought it back, I found that it had loosened up enough that the bike would sit there in gear, but we still couldn't get it into neutral.

This is the tests I've done to rule out some of these theories I've read about and people have said they have done.

First off I got out my grandfather's trusty fish scale, tied it to a rope to see how many pounds it takes to pull the lever. The scale says 20 lb.

Next I took the ball ramps apart, clean them up, and attached three Earth magnets to the bottom plate. Then I set it on top of my vise, so that it when it was turned it would hit against the vice Jaws. Not that this is the actual distance that the cable would pull the ramp, but it is a distance that I can repeat for what I'm looking for.

Next, using the stock 3/8 diameter ball bearings, I measured how far the plates moved apart, and then repeated the same test using the 13/32 ball bearings, which are the next size larger. Both ball bearings spread the plates exactly the same distance.

Next, I took a set of regular ball ramps, and mismatched them to see what the lift would be. I did manage to gain .010 using the stock upper plate, with an easy pull bottom plate. Switching them the other way, it would not lift it at all. The problem is the slots on the two plates do not match up.

I did reassemble the bike, using the easy pull bottom plate and a regular top plate. Readjusted the clutch, and when I adjust the slack out of the cable you can see that there's only a quarter inch of threads where there is normally half inch better.

This did add 4 lb to the clutch handle pull, and did absolutely nothing on helping me find neutral.

Next we'll move to the handle to see if anything's loose up there. I am also in contact with HDM, on handle designs. This is because I have another bike sitting right next to it with a different style handle on it that has absolutely no problem getting into neutral.

More info to come as I do research

Last edited: