beast30

Member

Well I had my 00' husky on the dyno a few weeks back, I wasn't really impressed with the numbers thats for sure. 91 Hp and 102 tq, which from last year drop almost 10hp and 15 tq........The only thing different from a year ago was i installed those big city thunder baffles, perhaps not the best decision I've made, but what the hell.

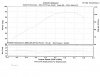

So I'm planning on chopping the orginal baffles a few inches and going back with those. My question is that (hopefully i can get the attachment to post) my air/ fuel ratio isn't to bad off but was thinking of upping 1 intermediate jet size to compensate for the lean condition between 3000-4000 rpm. I don't have a tch on my bike but in 3rd gear going about 35MPH it seems to miss alittle. Everything checks out on the carb, clean and no intake leak. Currently have V&H big shots 2/2 exhaust with a .295 inter and a 68 main.

The other thing I went to adjust my idle today and check the position of my accell pump. I ended counting the full turns in on the accell pump adjustment and found it to be at least 5-6 turns out from lightly seated. I know for a fact that I didn't adjust it out that far a few months back. The screw was so loose it almost popped out (no spring tension). So I adjusted out 2 turns and it seems to be good went out for a ride afterwards.

So I'm planning on chopping the orginal baffles a few inches and going back with those. My question is that (hopefully i can get the attachment to post) my air/ fuel ratio isn't to bad off but was thinking of upping 1 intermediate jet size to compensate for the lean condition between 3000-4000 rpm. I don't have a tch on my bike but in 3rd gear going about 35MPH it seems to miss alittle. Everything checks out on the carb, clean and no intake leak. Currently have V&H big shots 2/2 exhaust with a .295 inter and a 68 main.

The other thing I went to adjust my idle today and check the position of my accell pump. I ended counting the full turns in on the accell pump adjustment and found it to be at least 5-6 turns out from lightly seated. I know for a fact that I didn't adjust it out that far a few months back. The screw was so loose it almost popped out (no spring tension). So I adjusted out 2 turns and it seems to be good went out for a ride afterwards.

Attachments

-

105.5 KB Views: 66