There have been quite a few questions lately about popping and back firing. I have also been asked about exhaust and gaskets lately so I thought I would throw this out there for all of you to dwell on.

This is not a scientific study or of any confirmed research backed up by dyno testing or any of that, just my own personal experience with exhausts.

I have 5 sets of exhaust in the garage right now as I still haven't found that one pipe that I really like. I am a fan of the Stainless Creations though. I like not having chrome that gets ruined no matter how well you try to take care of it. I am also a devout 2 into 1 believer!

I'm going to break this up into 3 segments; gaskets, pipes, baffles.

Remember this is just my 2 cents so if you don't agree then you don't agree and if you have information to add then by all means add it here.

Gaskets come in lots of styles. Old HD gaskets and exhaust flanges used to be just one bolt/stud and the flanges were part of the pipe. They used to be a real pain in the ass on my old shovelhead. The new Evo gaskets are what we all have now with two studs. Some special motors like racers use a 4 bolt pattern for a better seal.

Here are early style single stud gaskets:

Here are the dual stud gaskets we use today:

Gasket styles: There is the early style and later style. Some call the later style Screaming Eagle gaskets. Early style are flat and later style are tapered. A lot of companies are now using metal crush gaskets similar to what you see on a spark plug. Here is some examples of these in the next photo.

I used the tapered style because they were all the rage and everyone insisted that you use this style. But over the years with lots of pipe changes and maintenance I've personally come to believe this style sucks. It took an old HD rider to make me believe it but when you get hit upside the head it makes you think a little more!

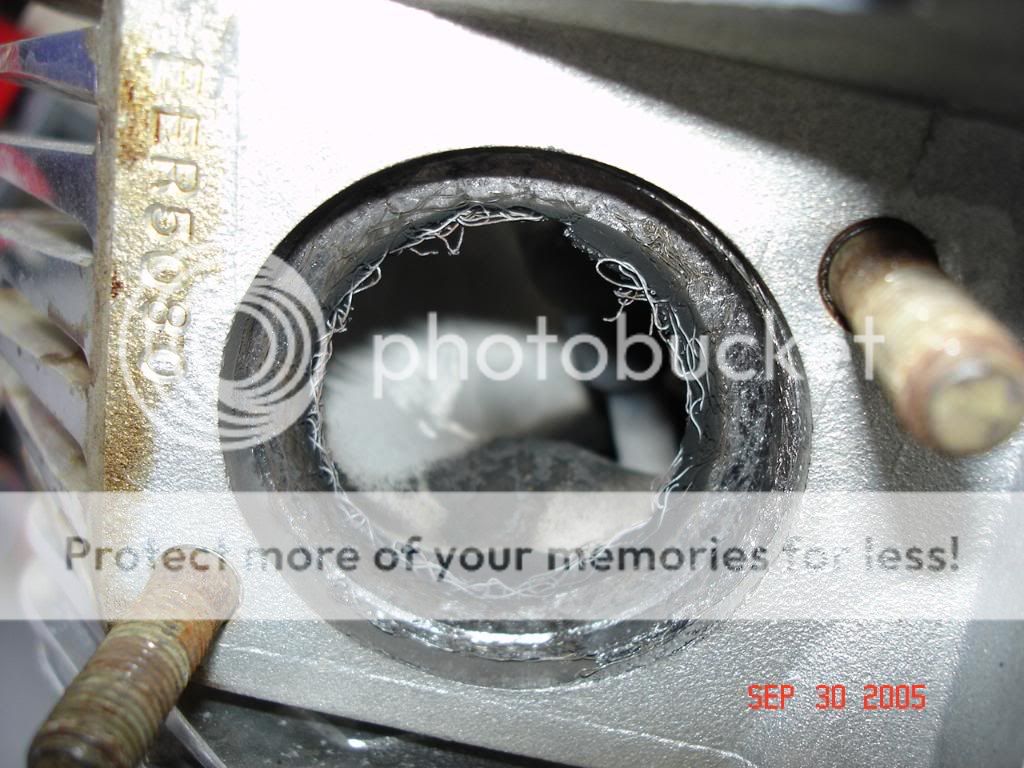

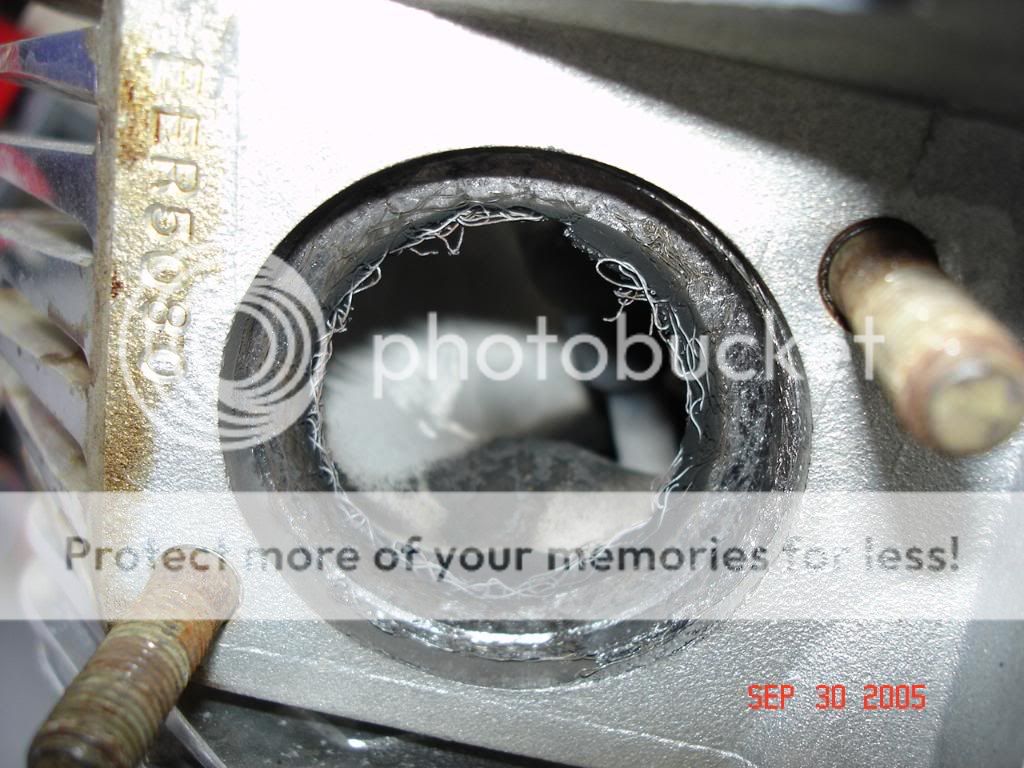

Here is a picture of the tapered style that claims to be soooooo gooooood!!! All the crushed material gets squeezed out into the exit chamber restricting flow to a small degree.

Here are the early style (flat) gaskets: Nice and clean! (Just ignore those two broken studs! :angry: )

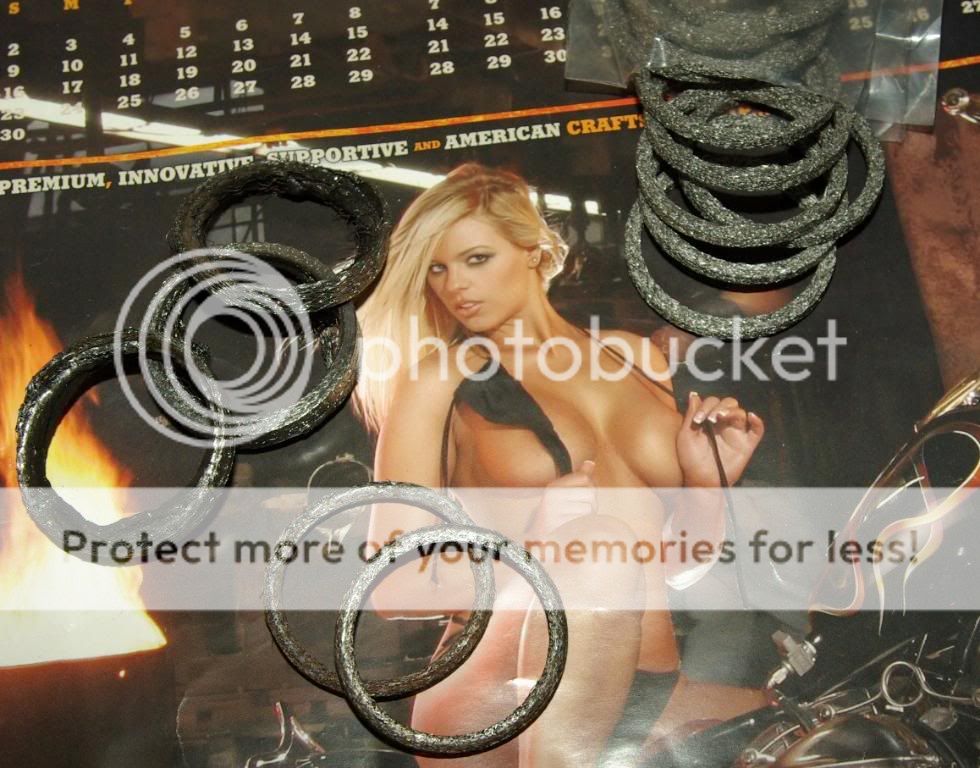

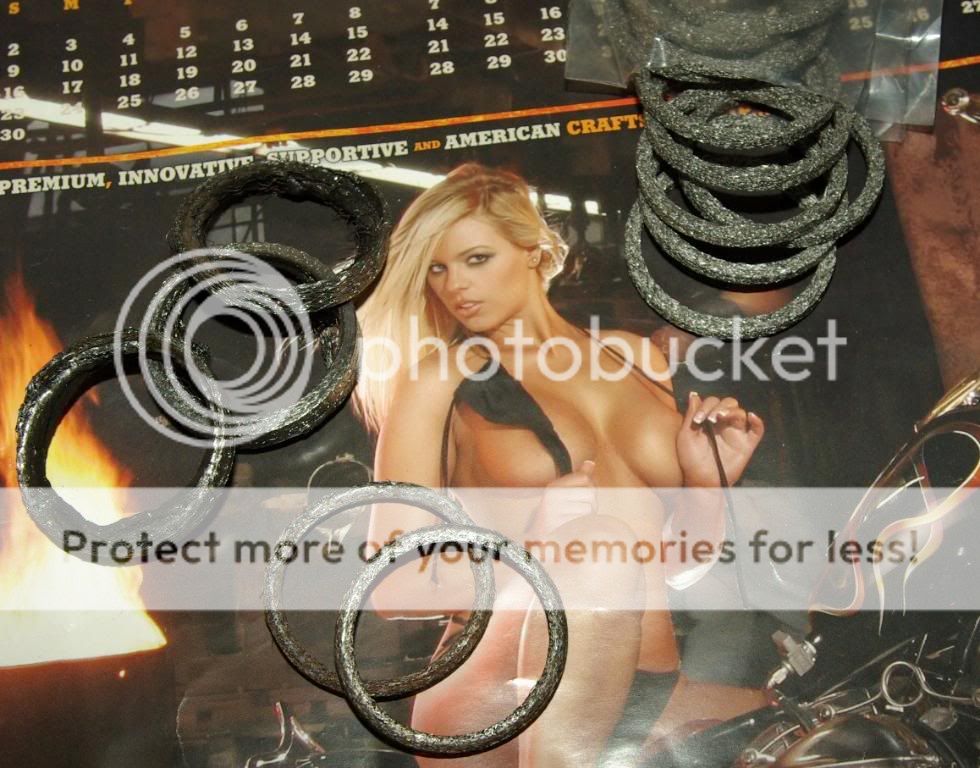

Here is some used gaskets I've pulled out of my motor. You can easily see the difference between the tapered and the flat styles. I like the clean flat style gaskets over the crushable. I buy them from Shovelheadkicker on eBay.

Now, everyone here........... Ok, let me rephrase that. The 10% here that don't have BR

may have other brands built by who knows who! All of our Evo style pipes have collars on the ends of the pipe that are used with the flange to mount the pipes to the heads of our motors.

may have other brands built by who knows who! All of our Evo style pipes have collars on the ends of the pipe that are used with the flange to mount the pipes to the heads of our motors.

I've seen from the many pipes I have that these collars can be of various sizes/widths.

I'm referring to the size of the collar on the end of the pipe that the flange rests against.

Here is three pipes I have and they have different collars on them. Some are real clean and smooth and others are rough and unfinished. These all affect the seal when you mount them up. Hard to tell in this photo but all the collars are not all the same size.

So, what’s important here is to ensure when you put your pipes on that you get a good seal on the heads when you are torqueing down your pipes. I use the flat style gaskets and after many a rides listening to all the popping and back-firing on startup I realized I didn't have a good seal on the gaskets. No matter how tight I tried to get them! I even gave up on the Ghetto Blasters that were the worst. (So I sent them to BBChopper :roll: ).

But, what I figured out was the problem was that I wasn't getting a good enough seal on the exhaust ports! :bang: The flanges were tight against the collars on the pipe when bottomed out but still not enough to give a good seal.

So what I did was double up on the old style gaskets and guess what happened? Almost all of my popping and backfiring was eliminated.

It took a lot of trial and error but I eventually figured it out on my own with a little help from that "slap on the back of the head" from a knowledgeable old mechanic!

The baffles. I don't know anything about baffles............ Except that you need some kind of backpressure for your motor. There are many styles of baffles out there. Every pipe maker has their own with testaments that it will produce more horsepower that all the rest with claims of an extra 20hp if you use them.

Here is a variety of baffles:

Bottom line though is experimentation is the key to a properly tuned motor.

I like the website "Nightrider" which has more information on exhaust than you need. This is the website that I used when I put my washers in my pipes that I show off here on this site.

NIGHTRIDER.com - Motorcycle Performance Information

Niterider also has lots of infromation on exhaust length and how the exhaust temperature, gas speed, exhaust valve duration and the RPM the engine is running effect the motor. See that here:

Exhaust Length

This is also the site that taught me about the washer baffle I mentioned earlier.

Exhaust Systems

Here are mine I installed in my pipes:

So what I have done here is just confuse you probably on all the options out there but understand that if you don't have a good seal on you exhaust ports you are going to have popping and backfiring! :argue:

Also understand there are many more variables to consider: Intake seal leaks, carburation (this is extensive) and valves and timing issues. All of these can lead to popping and backfiring. But more than likely it's either exhaust, intake or carburation so if you can at least elliminate exhaust then you are on your way to elliminating most of that popping and backfiring.

Do understand though on some pipes you most likely will have some popping on deceleration just due to pipe design that is more for style than performance or efficiency.

All right "that is all I have to say about that"!!

By the way, that old HD mechanic is going to slap you upside the head also if you don't verify a tight seal on your exhaust ports!!!!! :lol:

:flag: :flag:

:flag:

This is not a scientific study or of any confirmed research backed up by dyno testing or any of that, just my own personal experience with exhausts.

I have 5 sets of exhaust in the garage right now as I still haven't found that one pipe that I really like. I am a fan of the Stainless Creations though. I like not having chrome that gets ruined no matter how well you try to take care of it. I am also a devout 2 into 1 believer!

I'm going to break this up into 3 segments; gaskets, pipes, baffles.

Remember this is just my 2 cents so if you don't agree then you don't agree and if you have information to add then by all means add it here.

Gaskets come in lots of styles. Old HD gaskets and exhaust flanges used to be just one bolt/stud and the flanges were part of the pipe. They used to be a real pain in the ass on my old shovelhead. The new Evo gaskets are what we all have now with two studs. Some special motors like racers use a 4 bolt pattern for a better seal.

Here are early style single stud gaskets:

Here are the dual stud gaskets we use today:

Gasket styles: There is the early style and later style. Some call the later style Screaming Eagle gaskets. Early style are flat and later style are tapered. A lot of companies are now using metal crush gaskets similar to what you see on a spark plug. Here is some examples of these in the next photo.

I used the tapered style because they were all the rage and everyone insisted that you use this style. But over the years with lots of pipe changes and maintenance I've personally come to believe this style sucks. It took an old HD rider to make me believe it but when you get hit upside the head it makes you think a little more!

Here is a picture of the tapered style that claims to be soooooo gooooood!!! All the crushed material gets squeezed out into the exit chamber restricting flow to a small degree.

Here are the early style (flat) gaskets: Nice and clean! (Just ignore those two broken studs! :angry: )

Here is some used gaskets I've pulled out of my motor. You can easily see the difference between the tapered and the flat styles. I like the clean flat style gaskets over the crushable. I buy them from Shovelheadkicker on eBay.

Now, everyone here........... Ok, let me rephrase that. The 10% here that don't have BR

I've seen from the many pipes I have that these collars can be of various sizes/widths.

I'm referring to the size of the collar on the end of the pipe that the flange rests against.

Here is three pipes I have and they have different collars on them. Some are real clean and smooth and others are rough and unfinished. These all affect the seal when you mount them up. Hard to tell in this photo but all the collars are not all the same size.

So, what’s important here is to ensure when you put your pipes on that you get a good seal on the heads when you are torqueing down your pipes. I use the flat style gaskets and after many a rides listening to all the popping and back-firing on startup I realized I didn't have a good seal on the gaskets. No matter how tight I tried to get them! I even gave up on the Ghetto Blasters that were the worst. (So I sent them to BBChopper :roll: ).

But, what I figured out was the problem was that I wasn't getting a good enough seal on the exhaust ports! :bang: The flanges were tight against the collars on the pipe when bottomed out but still not enough to give a good seal.

So what I did was double up on the old style gaskets and guess what happened? Almost all of my popping and backfiring was eliminated.

It took a lot of trial and error but I eventually figured it out on my own with a little help from that "slap on the back of the head" from a knowledgeable old mechanic!

The baffles. I don't know anything about baffles............ Except that you need some kind of backpressure for your motor. There are many styles of baffles out there. Every pipe maker has their own with testaments that it will produce more horsepower that all the rest with claims of an extra 20hp if you use them.

Here is a variety of baffles:

Bottom line though is experimentation is the key to a properly tuned motor.

I like the website "Nightrider" which has more information on exhaust than you need. This is the website that I used when I put my washers in my pipes that I show off here on this site.

NIGHTRIDER.com - Motorcycle Performance Information

Niterider also has lots of infromation on exhaust length and how the exhaust temperature, gas speed, exhaust valve duration and the RPM the engine is running effect the motor. See that here:

Exhaust Length

This is also the site that taught me about the washer baffle I mentioned earlier.

Exhaust Systems

Here are mine I installed in my pipes:

So what I have done here is just confuse you probably on all the options out there but understand that if you don't have a good seal on you exhaust ports you are going to have popping and backfiring! :argue:

Also understand there are many more variables to consider: Intake seal leaks, carburation (this is extensive) and valves and timing issues. All of these can lead to popping and backfiring. But more than likely it's either exhaust, intake or carburation so if you can at least elliminate exhaust then you are on your way to elliminating most of that popping and backfiring.

Do understand though on some pipes you most likely will have some popping on deceleration just due to pipe design that is more for style than performance or efficiency.

All right "that is all I have to say about that"!!

By the way, that old HD mechanic is going to slap you upside the head also if you don't verify a tight seal on your exhaust ports!!!!! :lol:

:flag:

:flag:

:flag: