Posted with permission from Phil.

SuperMax Belt Drives For Harley-Davidson Motorcycles

Many of you know that I promote SuperMax at every opportunity. I do this cause I think they provide a great product. SuperMax is not new to the scene. They have been in business for many years.

Phil developed a dual belt drive system for Harley's many yeas ago. This was way before HD had the foresight to do it!

I was the recipiant of one of these dual belt drives back in 82 or 83. Phil developed a special poly clutch hub with the starter ring on it and all we had to do was send in your inner primary and swing arm for some modification.

My 81 Wide glide with dual belts on it:

Many of you here are familiar with "rotating mass". This is the centrifugal forces created from a rotating object or something like that! You Engineers on here can describe it better than I can.

You Engineers on here can describe it better than I can.

Phil's system used poly sprockets and eliminated many pounds of material to your existing system. Just think of how much weight we have in our clutch hub and shell, chain and sprockets!!! Can you imagine eliminating a good majority of this weight?

Here are a couple example of SuperMax's sprockets;

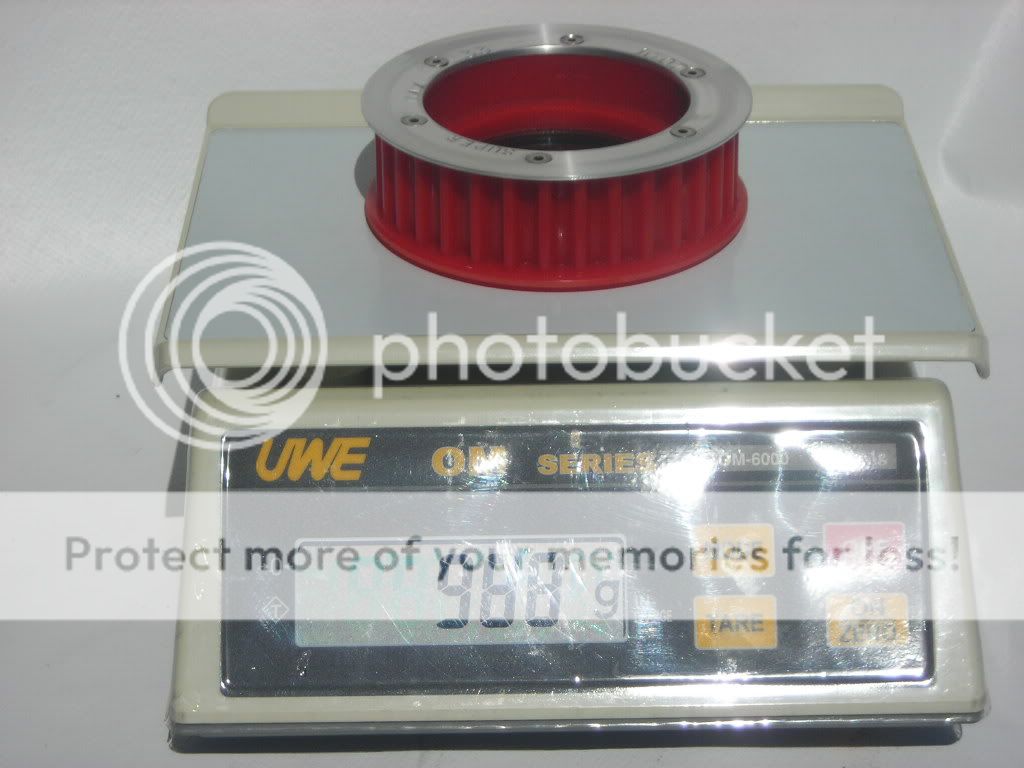

Your stock pulley:

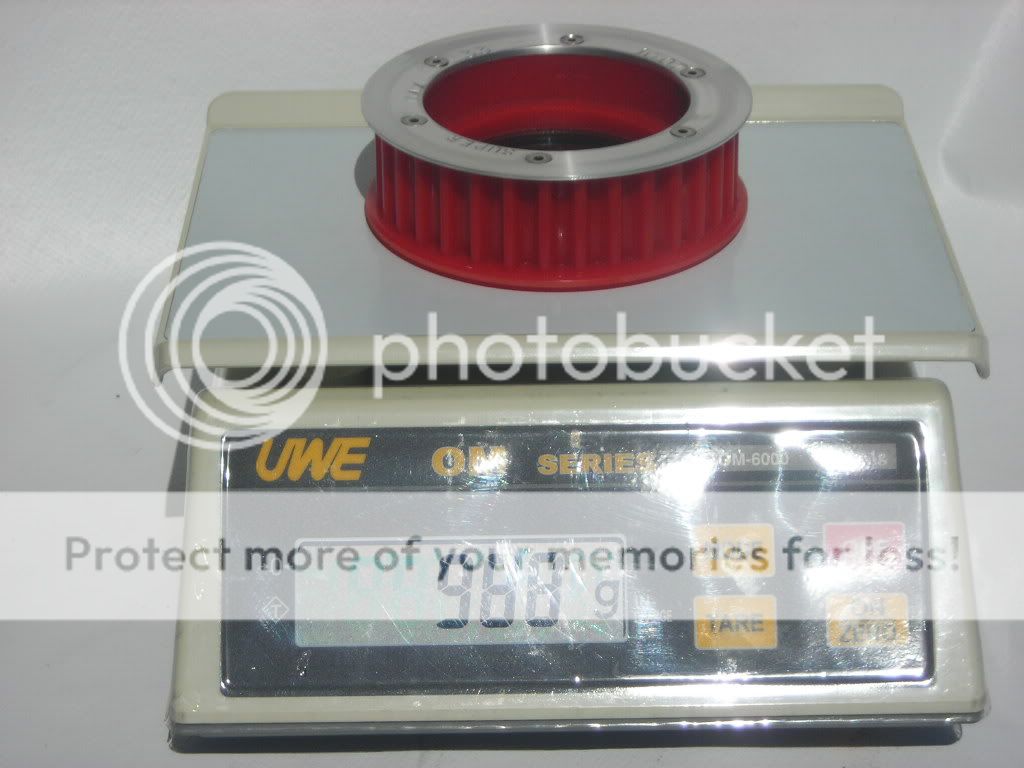

SuperMax's pulley:

Wow, about a 60% savings if my math is correct. Just as racers try to use the lightened wheels and brakes these poly sprockets help achieve the same thing.

W8less Rotors is doing the same thing with rotors using a light weight material I think called "metal matrix composite (MMC)".

Anyway with all the threads on here about belts sprockets and squealing I thought I would post another option you have in eliminating this problem. On our 05 and newer bikes BDM went with a Teflon coated sprocket but it eventually wears and then you are back to the squeal. 04 and older just have to live with it or carry a can of silicone with them.

But SuperMax can do something that will end your squealing issues forever. They can take your pulley and turn it down and pin/glue on a poly overlay on it that will last you for the rest of your days with the bike.

What's great about this too is he can mill your sprocket down then send it out for powder-coating or chrome then put his overlay on it. Kool option here.

As for durability.......... Well my old Shovel ran it for over 25 years and I never had to replace the belt or pulleys and I DID put a lot of miles on that thing!

Phil gave me permission to print this up. Not a sales thing or anything like that just giving you guys another option that I know of and have had personal experience with. :2thumbs:

Many here also may want to know what Phil rides today. You may not believe it but he still rides an old Pan/Shovel Stroker motor with a magneto ignition. Pretty kool old bike and check out the seat.

You guys ever get down to Arizona check him out.

The man that created the modern dual belt drive.

SuperMax Belt Drives For Harley-Davidson Motorcycles

Many of you know that I promote SuperMax at every opportunity. I do this cause I think they provide a great product. SuperMax is not new to the scene. They have been in business for many years.

Phil developed a dual belt drive system for Harley's many yeas ago. This was way before HD had the foresight to do it!

I was the recipiant of one of these dual belt drives back in 82 or 83. Phil developed a special poly clutch hub with the starter ring on it and all we had to do was send in your inner primary and swing arm for some modification.

My 81 Wide glide with dual belts on it:

Many of you here are familiar with "rotating mass". This is the centrifugal forces created from a rotating object or something like that!

Phil's system used poly sprockets and eliminated many pounds of material to your existing system. Just think of how much weight we have in our clutch hub and shell, chain and sprockets!!! Can you imagine eliminating a good majority of this weight?

Here are a couple example of SuperMax's sprockets;

Your stock pulley:

SuperMax's pulley:

Wow, about a 60% savings if my math is correct. Just as racers try to use the lightened wheels and brakes these poly sprockets help achieve the same thing.

W8less Rotors is doing the same thing with rotors using a light weight material I think called "metal matrix composite (MMC)".

Anyway with all the threads on here about belts sprockets and squealing I thought I would post another option you have in eliminating this problem. On our 05 and newer bikes BDM went with a Teflon coated sprocket but it eventually wears and then you are back to the squeal. 04 and older just have to live with it or carry a can of silicone with them.

But SuperMax can do something that will end your squealing issues forever. They can take your pulley and turn it down and pin/glue on a poly overlay on it that will last you for the rest of your days with the bike.

What's great about this too is he can mill your sprocket down then send it out for powder-coating or chrome then put his overlay on it. Kool option here.

As for durability.......... Well my old Shovel ran it for over 25 years and I never had to replace the belt or pulleys and I DID put a lot of miles on that thing!

Phil gave me permission to print this up. Not a sales thing or anything like that just giving you guys another option that I know of and have had personal experience with. :2thumbs:

Many here also may want to know what Phil rides today. You may not believe it but he still rides an old Pan/Shovel Stroker motor with a magneto ignition. Pretty kool old bike and check out the seat.

You guys ever get down to Arizona check him out.

The man that created the modern dual belt drive.

:2thumbs:

:2thumbs: